The storage system of a computer has always been the slowest component in the chain. Your CPU has fast cache memory, which interacts much slower (yet still fast!) with RAM and then we have your systems disks, which are again orders of magnitude slower.

RAID or Redundant Array of Independent/Inexpensive Disks is a method of combining multiple disks into one to improve performance, reliability or both. With SSDs quickly taking over from mechanical hard drives, this presents us with a choice: HDD Raid Vs SSD Raid. There’s no absolute winner here, so let’s take a close look at the considerations.

A Recap Of RAID Levels

While there is no universal standard for RAID configurations, there are several so-called RAID “levels” that have become pretty commonplace. When we’re comparing HDD RAID technology against SSD RAID technology, it’s important to recap the pros, cons and number of drives you need for each type of RAID setup. Let’s go over them in short order:

- RAID 0 needs two disks, provides no redundancy but lots of speed and no disk space penalty

- RAID 1 needs two disks, provides redundancy, but only small speed gains and a 50% disk space penalty

- RAID 10 needs four disks, provides redundancy, provides fast reads, better write speeds and sacrifices 50% of disk space.

There are of course other more complex RAID levels (e.g. 1E, 5, 50, 6 & 60) but these three are the most common that typical users would be interested in.

HDD RAID Vs a Single SSD

We figure the most common reason someone might be wondering about RAID and how it relates to SSDs comes from this specific comparison. So we’ll get this one out of the way first.

Mechanical hard drives are pretty slow, so one popular way to get better throughput is by combining two identical drives into the RAID 0 configuration. The data is “striped” across both drives and they act as one hard drive, but with (theoretically) twice the transfer speed. Since each drive has a unique part of your data, you can always have both drives contributing to any operation.

Samsung 970 EVO Plus SSD 1TB

Sadly, when it comes to raw speed, a single SSD is always going to win out against a RAID 0 hard drive setup. Even the fastest, most expensive 10,000 RPM SATA III consumer hard drive only tops out at 200MB/s. In theory . So two of them in RAID0 would only manage a little under twice that.

Just about any SATA III SSD will get very close to the limit of the connection at 600MB/s. If we’re talking NVME SSD s using the PCIe protocol, then typical read speeds exceed 2000MB/s.

In other words, if pure performance is what you’re looking for, a single SSD will always beat a pair of mechanical drives. Even if they are the fastest mechanical drives in the world.

The same goes for reliability and data protection. If you have a RAID 10 setup with four hard drives, you still get double the drive speed and you can lose a drive without losing any data. Despite this, a single SSD will still be a more reliable solution. SSD have a limited number of writes before they can no longer overwrite existing data, but you can still read all the data on the disk.

Spontaneous failure of an SSD is incredibly uncommon, but you always have the option of running two SSD in RAID 1. There’s no significant speed benefit, but one drive can fail completely without data loss. We wouldn’t recommend spending money on a RAID 1 SSD setup purely for data safety. It’s far more cost-effective to simply back up your hard drive image to an affordable external drive or the cloud, since most desktop systems are not mission critical.

HDD RAID vs SSD RAID: General Considerations

Now that we’ve dealt with the single SSD scenario, let’s talk about direct RAID-to-RAID comparisons. That is, mechanical drives in RAID compared to SSDs in RAID. There are three main aspects to consider: performance, price and data reliability. Let’s look at each one in more detail.

Performance

You will probably be unsurprised to hear that an SSD RAID configuration will always beat any mechanical drive RAID setup in raw performance. The real question is how much performance you’ll gain from running SSDs in RAID and whether it’s worth it. This is a complicated question.

One factor is hardware versus software RAID. A dedicated hardware RAID controller will provide better performance than a software-based solution. Additionally, as speed increases, other components in your computer might become a limiting factor or “bottleneck”.

For example, in day-to-day use there’s little difference between a SATA III SSD and an M.2 NVMe PCIe drive. despite the latter being five or six times faster. Games don’t load noticeably faster and applications aren’t necessarily more snappy. Workloads such as video editing or professional applications involving massive dataset analysis, on the other hand, will eat as much bandwidth as you have to offer.

This means that putting two SSDs in RAID 0 probably won’t improve the average user experience and the cost could be better spent elsewhere in the system

Price!

Although SSDs have come down a lot in price over the last few years, they are still many times more expensive on a per-gigabyte basis than mechanical drives. In fact, mechanical drives have been pushing capacity of late since they can’t compete on performance.

This makes SSDs unattractive as redundant mass storage. Mechanical drives in purely-redundant or redundant and performance RAID configurations are still very relevant and cost effective for desktop users. If you run a home NAS (network attached storage) system for streaming or file sharing, it’s the most practical choice.

If you absolutely need the speed of two SSDs in RAID 0 or have a mission critical drive that benefits from RAID 1, you’re looking at twice the price of running a single drive. Only you can decide if 200% of the cost is worth the advantages of either option.

Reliability & Endurance

SSD endurance is something we’ve written about before and it’s a complex comparison with mechanical drives. SSDs wear out when they’ve been written to too much. However for modern drives, write endurance is far beyond what most users will ever need.

A complete loss of data even when an SSD cannot be written to, is very unlikely. In many ways RAID exists because mechanical drives are prone to failure in the first place. Head to head, SSDs are so much more reliable that they don’t make redundant RAID compelling.

No Clear Answers

As you can see, there is no situation where the answer will always be HDD RAID or SSD RAID (or otherwise). It’s very dependent on your specific needs. Nonetheless, we can provide some general guidelines:

- Most users won’t benefit from SSD RAID speed improvements.

- HDD RAID is still best for mass storage.

- SSDs are reliable enough to make RAID sensible only for mission-critical uses.

With a clear picture of where each approach works best, you should have a much better idea which option makes the most functional and economic sense for you.

- WhatGeek x 3inuS Kebohub EE01 Mechanical Keyboard Review

- Mobile Pixels Duex Max Portable Monitor Review

- Trifo Lucy: The AI Robot Vacuum and Mop

- Review of Anycubic Kobra Max 3D Printer

- The OBSBOT Tiny 4K: an Impressive Webcam for PC & Mac

Sydney Butler is a social scientist and technology fanatic who tries to understand how people and technology coexist. He has two decades of experience as a freelance computer technician and more than a decade as a technologies researcher and instructor. Sydney has been a professional technology writer for more than five years and covers topics such as VR, Gaming, Cyber security and Transhumanism. Read Sydney’s Full Bio

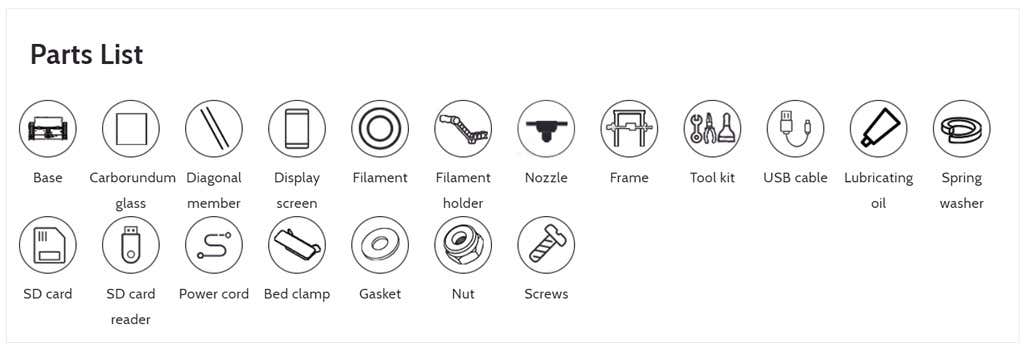

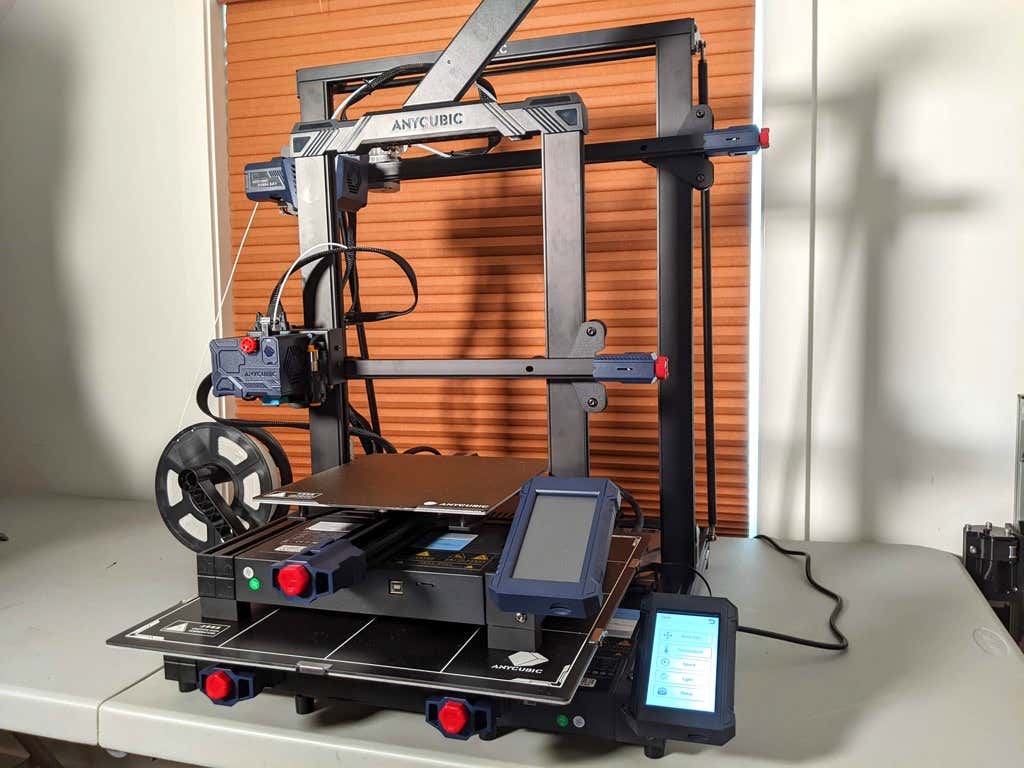

3D printer manufacturer, Anycubic, recently released two new printers—the Anycubic Kobra and its bigger, badder uncle, the Anycubic Kobra Max. We were interested in testing both products in our hunt for the best entry-level 3D printers. We’re looking for ease-of-use and affordability, as well as build and print quality.

We’ve published a number of 3D printer reviews from Anycubic—for both FDM printers like the Anycubic Vyper that print with spools of filament and SLA resin 3D printers like the Anycubic Photon Mono X 6K that use a liquid resin as its raw material—and we can say that the Kobra Max has quickly become one of our favorites.

Features of the Anycubic Kobra Max 3D Printer

The most obvious feature of this printer is its size. It is absolutely massive. That means you can print huge items in a single piece. Think of a full helmet or an entire ukulele—these are things you couldn’t print in one piece on a normal-sized 3D printer. Truly, the word “Max” doesn’t sufficiently capture just how big this printer is. Good luck fitting the packaging into your trash or recycling bins!

We were skeptical that a Cartesian printer of this size (which relies on a moveable print bed) would perform well since it has a lot of weight to move around. Admittedly, it’s not the speediest printer out there because of those design tradeoffs, but it works great.

The Kobra Max has an impressive list of technical specifications:

- Leveling: Automatic, 25 points leveling using the Anycubic Leviq technology

- Panel area: 7.95 in² / 51.3 cm²

- Filament run-out detection: support

- Printing material: PLA / ABS / PETG & TPU

- Nozzle size: ø 0.4 mm (replaceable)

- Nozzle temperature: ≤ 500 °F / 260 °C

- Hot bed temperature: ≤ 194 °F / 90 °C

- Average speed: 3.1 – 3.9 in./s (80mm/s – 100m/s)

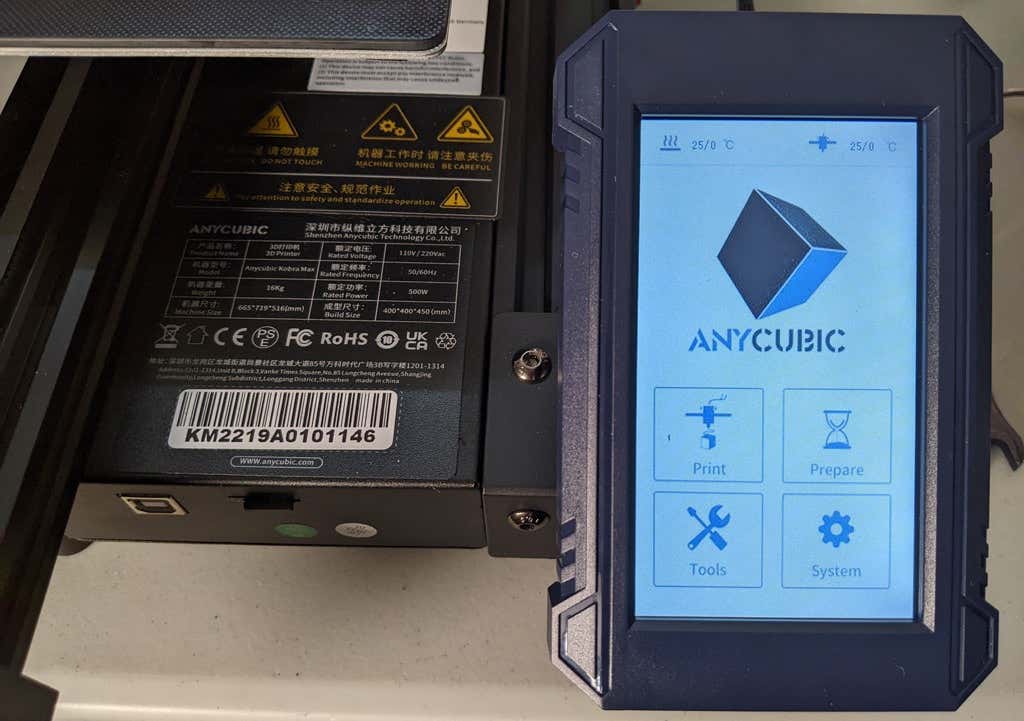

- Control panel: 4.3 inch LCD touch screen

- Z-axis: double threaded rod

- Print size: 17.7 x 15.7 x 15.7 in. / 45 x 40 x 40 cm (HWD)

- Build volume: 19.02 gal. / 72.0 L

- Machine dimensions: 72 x 71.5 x 66.5cm

As far as we can tell, the extruder is identical to the extruder and print head on the Anycubic Vyper. Furthermore, the Kobra Max has the same automatic bed-leveling system as the Vyper. The system uses a pressure sensor instead of an inductive sensor.

The bed-leveling sensor is right on the nozzle itself, ensuring that it can probe every printable part of the bed. And since the sensor is pressure-based, you could replace the glass bed with any other material and the bed-leveling system will still work. (Inductive sensors require metal to work, so you won’t find them on printers with glass beds.)

Since the Kobra Max’s printing platform is a rigid glass sheet, you can’t remove and flex it to pop your prints off. We prefer removable spring steel build plates, but glass is still a nice printing surface. If your printer doesn’t have a removable bed, glass is ideal because you can use metal scrapers to remove your prints without worrying about scratching the surface.

The LCD touchscreen is identical to the screens used on many other Anycubic printers. As usual, it’s responsive and easy to use.

A note about filament types: the Kobra Max will print with PLA, PETG, TPU, and ABS. However, if you really want to print with ABS and get the best possible results, the printer should be inside an enclosure. Given its size, it may be challenging to build a suitable enclosure for the Kobra Max.

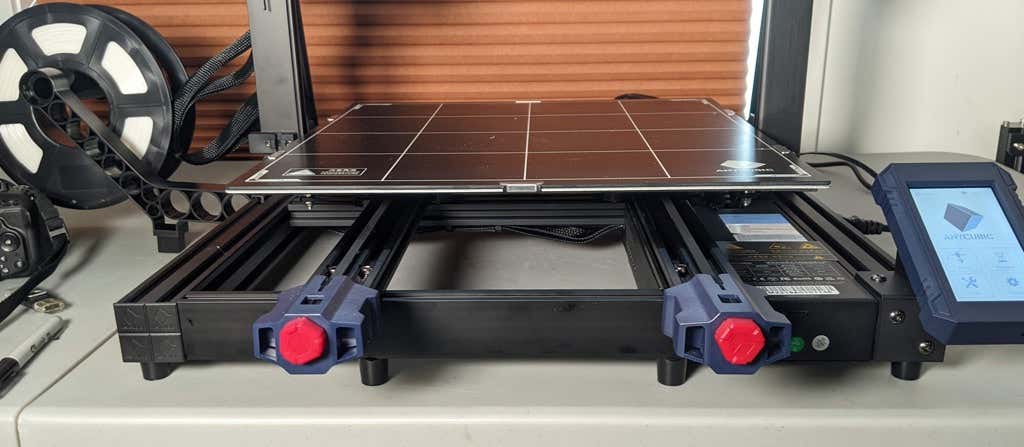

Assembling the Kobra Max 3D Printer

When assembling the new Kobra Max, make sure you have sufficient working space. Since the bed moves forward and backward, you need more space than you’d think. We put it on a 30” folding table, and when it’s printing, it needs about 36 inches, front to back.

Assembly of the Kobra Max is no more difficult than assembling the Kobra or Vyper. The only additional items are the diagonal braces which add stiffness to the frame, reducing mechanical vibration.

It took two people about 15 minutes to assemble. Double-check that you’ve cut all the zip ties used to stabilize the printer during shipping. There are a lot of them.

Calibration

The auto-bed-leveling system is easy to use. Anycubic recommends that you check the x- and the y-axes to make sure they don’t wobble. If they do, you can adjust the eccentric nuts until the wobbling stops. There was no wobble on our printer, so we didn’t have to do anything.

Additionally, the x- and y-axes have belt tensioners. We needed to slightly tighten the x-axis on ours. The tensioners are easy to use and are features a lot of other printers lack. Who wants to take apart the extruder assembly just to tighten the belts? Not us, and probably not you.

Build Quality of the Kobra Max

Due to the addition of the diagonal braces, the frame is really stiff. The dual z-axis screws are an improvement over the smaller Kobra. They virtually eliminated sagging of the x-axis assembly.

The spool holder sits on the base of the printer, reducing wobbling when printing tall items. It’s better than having the spool on the top like on the Kobra.

This printer is built with aluminum extrusions with aesthetically-pleasing plastic covers for the hotend and the tenionsers. It’s got an optical z endstop. The x and y endstops are mechanical. The whole thing feels solid.

First Print

For the first print, we used the test file provided by Anycubic. Appropriately, the owl is about twice the print volume of the owl test print that comes with the smaller Kobra. Given the bowden setup (which makes sense for a printer this size), we were surprised that the ears on the owl turned out so well.

The ears look better than they did on the owl printed on the Kobra which has a direct drive extruder system. We suspect that’s due to the slower print speed. Many times, retractions on bowden extruders will create artifacts, but we didn’t notice any blobs or stringing. It approaches the quality you’d expect from a direct-drive.

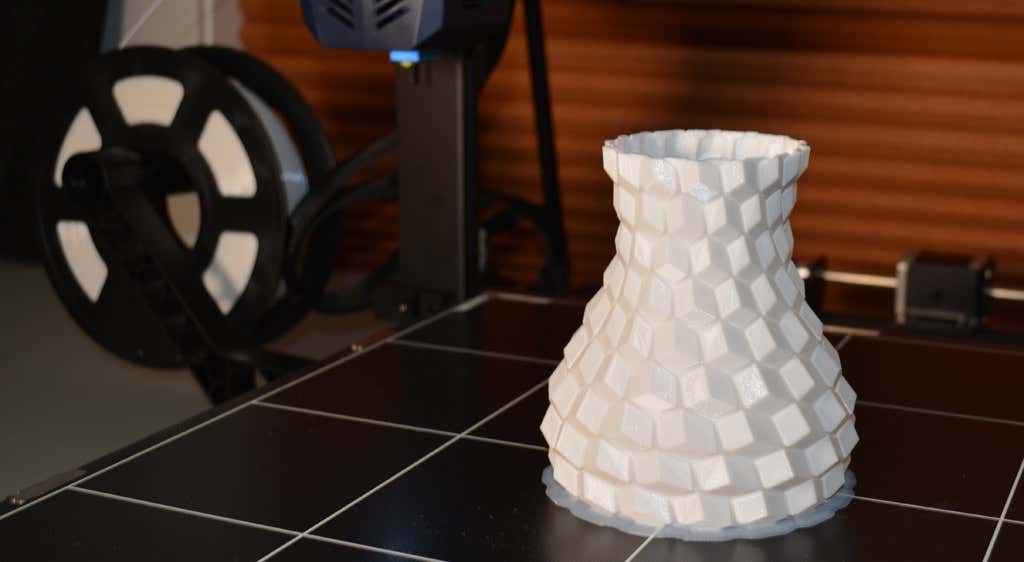

Next, we printed a vase with a large, flat base with a 0.2mm layer height. Removing prints from the glass bed is certainly not as easy as removing prints from smaller, flexible beds, but it’s not a deal-breaker either. We didn’t have any adhesion problems. The prints didn’t release when the glass bed cooled, which is what we expected and hoped for.

Curious what the power requirements would be for a printer this size, we were worried we wouldn’t be able to run multiple printers on the same circuit. We measured the power usage while the Kobra Max was printing, and, as expected, power usage is highest while the printer is warming up. Ours topped out at 473 watts. While printing, it was a more manageable 200-300 watts. We thought it would be more than that. You could probably run three of these printers on a 20 amp circuit.

Cut to the Chase

To drive home just how big the Kobra Max is, we put the Kobra on the bed of the Kobra Max. Insane. (We do not recommend you try this.)

A small printer is limiting, so if you find yourself printing large objects in small pieces and assembling them, consider buying a Kobra Max. If you’re new to 3D printing, keep in mind that it takes a long time to print big objects—potentially days and days. Typically, we’d recommend a smaller printer to beginners, but at the price point of $569.00 if you purchase on the Anycubic site, it’s worth considering as an entry-level printer.

One downside is that smaller prints will take a little longer than they would on a smaller, faster printer. That’s just physics. Bigger printers have more inertia to overcome and take longer to move. For example, the print time for our vase was thirteen hours. On our Prusa MK 2.5 with similar settings, it would have taken about twelve hours—not a huge difference.

*Special thanks to FormerLurker for help in reviewing AnyCubic’s Kobra Max 3D printer.

- WhatGeek x 3inuS Kebohub EE01 Mechanical Keyboard Review

- Mobile Pixels Duex Max Portable Monitor Review

- Trifo Lucy: The AI Robot Vacuum and Mop

- The OBSBOT Tiny 4K: an Impressive Webcam for PC & Mac

- Review of Anycubic’s Kobra 3D Printer

Maggie Marystone is a freelance technology writer, human rights worker, and storyteller based in Chicago. Read Maggie’s Full Bio